TRABO Techniek on the Hout Exhibition in Rotterdam.

WSB33 with Beam lift and Higher Worker

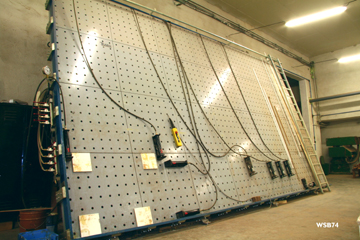

One of the larger presses delivered bij TRABO Techniek, a WSB74, net pressing dimensions 6.62 m x 3.68 m. By mounting the upper row of modules on site, the complete press could be transported in a standard container.

A large press, specially built for the manufacturing of large numbers of tabletops, length almost 10 m. Basically divided in 5 stations, each with 6 hydraulic cilinders and 3 mobile, pneumatically operated retainers.

Equipped with double vertical check beams and two hydraulic units (both with electronic control), allowing for simultaneous independent use of the left and the right side. It also means that the maximum horizontal press length is over 6.5 meters.

Retainers for use in the assembly of tabletop elements or other laminated constructions, as applied here on the frame press of Madurodam.

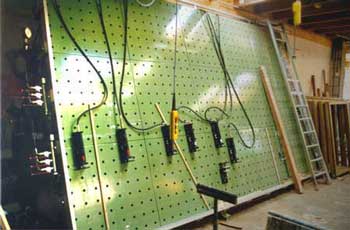

A WSB64, originally installed as a WSB63, height increased to 4 modules 4 years later.

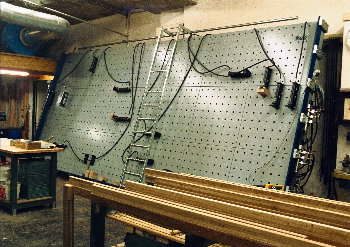

Originally built as a small frame press of 3x2 panels. On site enlarged for the present user and equipped with a movable guided ladder. Only the hydraulic lines to the cylinders had to be renewed because of the required greater length.

With electronic control (operating panel hanging from a rail above the press) and powder coating of the panels.

A double press with dimensions specially adapted to the manufacturing of doors, just leaving for a customer. A single hydraulic unit with separate pressure control and electronic actuation of the five hydraulic cylinders of both sides.

Extension of an existing WSB53 with 2x2 panels for a special project where longer elements are being assembled.